Visualization and monitoring

Visualization, monitoring and control – in the age of digitalization, ever higher and more specific demands are placed on these factors. With our future-oriented solutions in this area, there requirements can be met efficiently and reliably. By supporting standards, the systems can be designed openly and used flexibly.

With the help of our Modular Diagnostic Toolchain, test sequences can be defined, performed and monitored on the basis of diagnostic standards. We also have other software solutions, such as CANexplorer 4 for effective fieldbus monitoring. The modularity and intuitive handling allow flexible use and a wide range of actions.

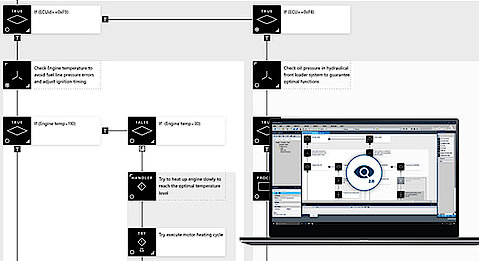

MDT® 2.0 with OPC UA

Next generation modular diagnostic tool for innovative machine park monitoring. Based on OPC UA, ODX and OTX standards.

- OPC UA Server & Client

- ODX 2.2.1 according to ISO 22901-1

- OTX according to ISO 13209

- Multi platform support

CANexplorer 4

Don’t lose any time during CAN bus diagnostics and benefit from the modular software for acquisition, processing, display and transmission of CAN data.

- Fieldbus analysis tool

- User-defined measurement setups

- Receive, process, send and abstract

- J1939 and CANopen protocol support

Case Studies - Process Monitoring

eControl mIO xt with OPC UA

For the German manufacturer of household and commercial appliances Miele, Sontheim has developed a touch-based control system for endurance tests that takes advantage of OPC UA… more

MDT® 2.0 – Modular diagnostic tool 2.0

In cooperation with several major mobile machinery OEMs, we have continued the success story of our MDT® (Modular Diagnostic Tool) and developed the next generation… more